- Home

- Factory Tour

Factory Tour

We run an independent manufacturing plant equipped with precision machinery to ensure the quality and cleanliness of our final products. This gives us tighter control over the production cycle and allows us to offer products at competitive prices.

Assembly room

We have 1000 square feet of class ISO 5 cleanrooms, which can fit up to 8 production lines and 200 assembly crew.

Every step of the assembly process is strictly monitored. As for cleaning, welding and sterilization packing and other key procedures, employees are trained and go through examination to earn work qualification. 100% of the staff members are trained.

Material controlMaterial selection is crucial to product quality. We seek suppliers for the best materials in the industry. As for purity, anti-static, temperature, humidity and other properties, certifications and other reports will be provided. We also actively work with suppliers to develop better materials and make mutually beneficial improvements.

Meanwhile, we have built a comprehensive system to authenticate material, keeping track of the whole process starting from development all the way through to assembly. There is a quality assurance contract for every key material signed with our supplier, making sure that the materials meet our requirements. Every year we will test the new material, making improvements based on the latest material in the business, developing our products with the most advanced material as best as possible. We have setup a complete protective system for our material, ensuring the stability of the material held in storage.

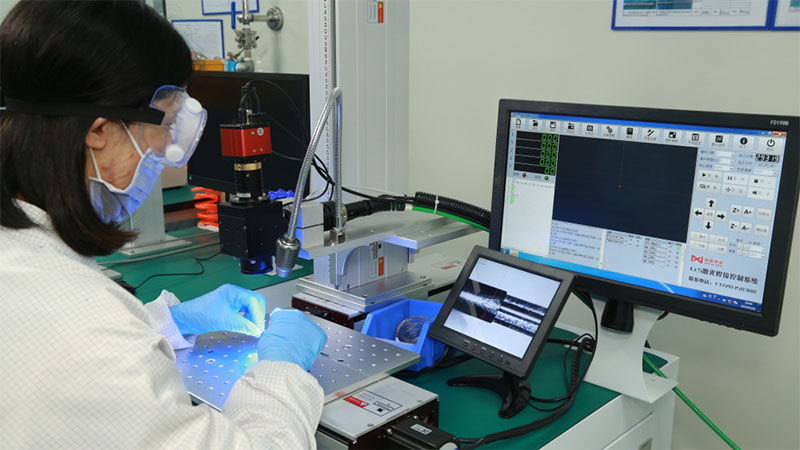

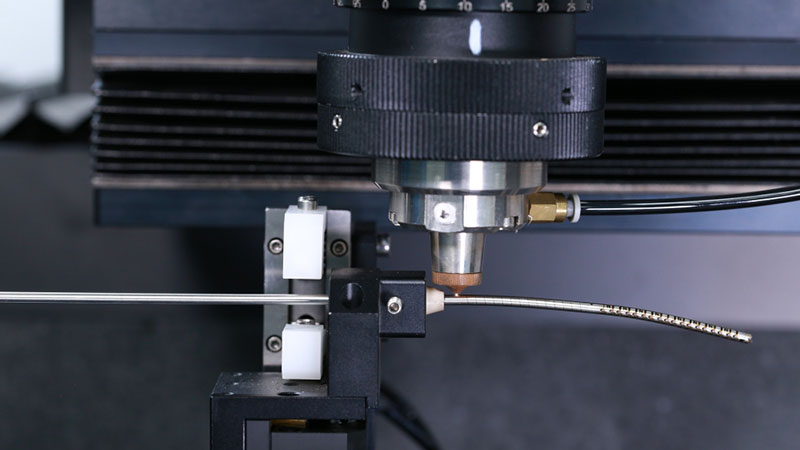

Production control and product quality inspectionWe have many staff members responsible for production control. Inspectors and technicians are well trained and strictly follow every inspection procedure. They keep track and control the production quality and sources, ensuring the final quality of the product.

We have an inspection station in every assembly room, effectively controlling the quality of our product during production, ensuring a minimal defective rate.

Regular quality meetings are held to keep track of the quality of products and re-examine quality control and production procedures. We will come up with a solution for any problem we find.

LaboratoryWe have built independent laboratory, electronics laboratory, chemistry laboratory, microorganism detection laboratory, sterilization laboratory, germ positive control room, equipment with more than 30 detection device, complete protocol and measuring system to ensure their inspection capability.

We will send the material to a third party for inspection annually, reassess the inspection procedure and equipment, ensuring the inspection reliability.